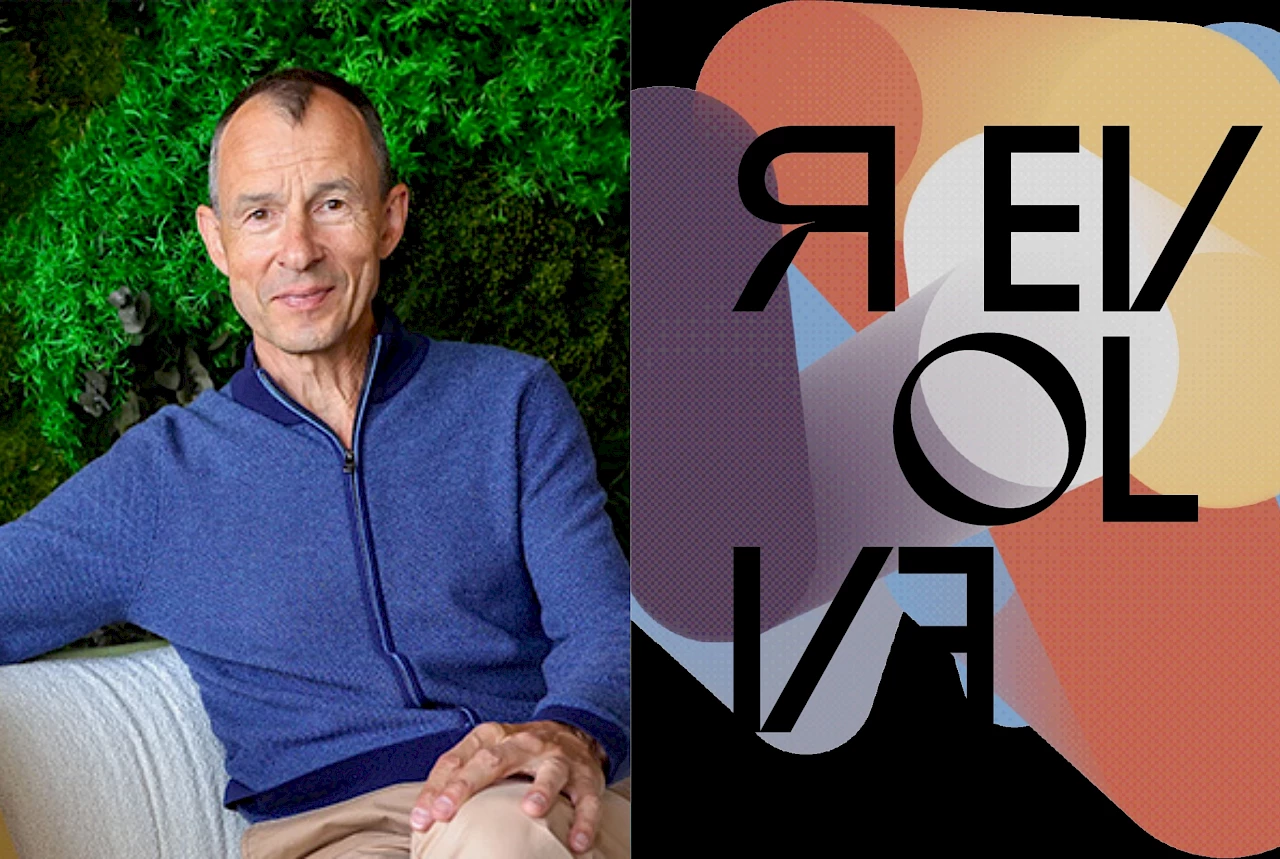

The partners in the EU project R‑evolve met for a three-day innovation camp in Copenhagen in September. The aim was to show tangible paths towards a circular economy—from product design and the manufacturing process through to new business models, with each stage being supported by the data in the Digital Product Passport (DPP). We spoke to Volker Weßels about key findings, the current status of the DPP and its practical implementation in companies.

Mr Weßels, what did you take away from Copenhagen for the industry?

The most valuable realization that dawned is that the digital product passport is much more than just a tool for compliance. If used correctly, it can strengthen the relationship with customers, for example through extended warranties or targeted product updates offered directly via the passport. This enables companies to develop and offer new services and stay in contact with their customers on a permanent basis. Another highlight is that products can often be improved with just a few targeted changes. This was demonstrated in a pilot project with students. A simple chair was adapted by means of small adjustments to turn it into a model that is easier to repair and refurbish. The result is not only technically convincing, but also economically plausible.

A simulation game on the digital product passport was even organized in Copenhagen. What was the objective?

We tried out how a governance framework works in practice—i.e. rules for who is obliged to provide reliable data, who is authorized to access which data and when, how the respective rights are distributed and how changes are logged. The simulation game simulated a public tender in the year 2032 under the ecodesign regulations that will then apply. The participants took on different roles. These included various units on the side of the two competing manufacturers—for example, in addition to the company management, purchasing, quality management and marketing—as well as suppliers, refurbishers, recyclers and national market surveillance bodies. This allowed us to test whether the set of rules can be practically implemented in day-to-day business and with changing requirements in addition to the technical standards of the product passport.

How does this fit into the European process?

We can imagine, for example, that elements of our governance framework could be incorporated in a European standard. If possible, this would supported by a mandate from the European Commission. The governance framework could thus be used in the furniture sector throughout Europe in order to establish the necessary trust in the DPP data. However, this process will take several years. Realistically, a corresponding delegated act for furniture (ESPR Implementing Regulation for Furniture) will not be adopted until 2028 or 2029, followed by an implementation period. The clarification process within the sector, which also takes time, can run in parallel. We expect full implementation by around 2030.

Where will the DPP change everyday life first: for manufacturers, retailers or customers?

Firstly, it affects the manufacturers, because in the future, there will be no market without DPP data. No piece of furniture will reach the market in the EU without a DPP. In concrete terms, because nothing will work without structured environmental data on carbon footprint, recycled content, recyclability, critical substances and energy consumption. If you don’t measure, document and digitalize this data, you won’t be able to store it in the product passport later on. The DPP becomes relevant for retailers and service centres as soon as they intervene in the products, for example during maintenance, repairs or upgrades. Corresponding entries must then be made in the passport. It is important that access rights and responsibilities are clearly regulated. The DPP also opens up new opportunities to establish direct customer relationships. This is usually easier to implement in the business customer sector (B2B) than in the private end customer sector, where the traditional retail trade often stands between manufacturers and users.

You mentioned the chair pilot project earlier. What exactly has been changed and why is it important?

In the chair pilot project, the project team systematically reworked the design and construction. Instead of the previous shell with a metal frame, a plastic solution was chosen in which fixing points can be integrated much more easily. The seat cushion is no longer glued, but simply clipped on so that it can be replaced or repaired without damage. The base frame can also be used flexibly for different models such as a swivel column, a four-legged base or a cantilever chair. This reduces the number of variants in the range. The resulting chair is easier to dismantle, easier to repair and more sustainable overall, as fewer individual parts are required and these can be more easily reused—a real step forward in both ecological and economic terms.

R‑evolve is working with nine pilots. Are there further examples and next steps?

A total of nine different pilot projects are currently underway, each testing different aspects of the circular economy in practice. Some of these pilots are still in the early stages, while others, such as a take-back project in the kitchen sector, are already further along. Here, used furniture is systematically reclaimed and checked for materials, hygiene and reuse. There are often special incentives for customers. The first practical tests are currently being carried out with IT partners in the area of digital product passports. The governance framework, i.e. the regulations for handling data, will be further developed on the basis of the experience gained in Copenhagen. The aim is to expand the successfully tested ideas to more companies on a larger scale and thus measurably drive forward the transformation of the industry.

How does R‑evolve contribute to the EU agenda with regard to the Green Deal and ESPR?

The Ecodesign for Sustainable Products Regulation (ESPR) defines the framework within which circular design, service models, data management and take-back schemes operate. The DPP is a central element here. R‑evolve is trialling how these requirements can be implemented in practice and in a cost-effective manner. Even if political decisions can fluctuate, the technical work continues uninterrupted. This is why pilot projects and their scaling are so important. We need reliable models that show how the circular economy works.

What advice would you give to companies that want to enter the market now?

First, they should do their data homework and check exactly which environmental and product data from the ESPR’s general catalogue (Article 5, Annex 1) they can already record correctly and where there are still gaps. Then structures need to be created. To do this, measuring points must be defined, data organized and clear terms and interfaces established. Clear processes are also needed. Who collects data, who checks it and who releases it? Finally, R‑evolve advises you to start small. Start pilot projects, test variants and document take-back cases. After all, data can only be utilized efficiently if it is available in a consistent digital format. That’s the key to success.

Mr Weßels, thank you for talking with us.

Volker Weßels is responsible for sustainability at the IBA and has been involved in European standardization for many years. He heads the European LEVEL programme (sustainability label for office furniture) and represents the IBA in the EU project R‑evolve. Further information is available at: https://www.linkedin.com/in/volker-weßels-655107b6/ and https://www.levelcertified.eu/.

Please note: R‑evolve is funded by the EU under the Horizon Europe programme (HORIZON-CL6-2024-CircBio-01–3). The Innovation Camp in Copenhagen brought together expertise from industry, science and politics; the focus was on circular business models, circular design and the digital product passport. The results will be incorporated into the ongoing pilot projects and into the preparation of future ESPR requirements.

Cover photo: IBA/R‑evolve